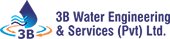

Reverse Osmosis (RO) Plants

Reverse Osmosis (RO) is a membrane based process technology to purify water for drinking purpose as well as by separating the dissolved solids from feed stream resulting in permeate and reject stream for a wide range of applications in domestic as well as industrial applications. It is seen from literature review that RO technology is used to remove dissolved solids, colour, organic contaminants, and nitrate from feed stream. Hence RO technology used in the treatment of water and hazardous waste, separation processes in the food, beverage and paper industry, as well as recovery of

organic and inorganic materials from chemical processes as an alternative method . This paper intends to provide an overall vision of RO technology as an alternative method for treating wastewater in different Industrial applications. The present short review shows applicability of RO system for treating efuents from beverage industry, distillery spent wash, ground water treatment, recovery of phenol compounds, and reclamation of wastewater and sea water reverse osmosis (SWRO) treatment indicating efficiency and applicability of RO technology.

Advantages of RO Process

- RO systems are simple to design and operate, have low maintenance requirements, and are modular in nature, making expansion of the systems easy;

- Both inorganic and organic pollutants can be removed simultaneously by RO membrane processes;

- RO systems allow recovery/recycle of waste process streams with no effect on the material being recovered;

- RO systems require less energy as compared to other technology; and

- RO processes can considerably reduce the volume of waste streams so that these can be treated more efficiently and cost effectively by other processes such as incineration

- The RO plant is normally operated at ambient temperature which reduces the scale formation and corrosion problems, because of antiscalent and biodispersent use, which will reduce maintenance cost

- The modular structure of the RO process increases flexibility in building desalination plants within a wide range of capacities.

FOR REVERSE OSMOSIS (RO PLANT)

|

|

|---|---|

| 3BWER-301 | Antiscalant |

| 3BWER-302 | Antiscalant& Antifoulant for iron, silica |

| 3BWER-303 | High pH Antiscalant |

| 3BWER-304 | Non oxidizing biocide & dispersant |

| 3BWER-305 | Membrane Passivator |

| 3BWER-306 | Low pH membrane Cleaner |

| 3BWER-307 | High pH membrane Cleaner |